What is FORMcard

The FORMcard is a handy, credit card sized piece of thermoplastic for making light work of any difficult plastic repair. When heated it becomes pliable and then it hardens again upon cooling.

The FORMcard only needs a glass of hot water to turn it from a rigid card into a mouldable material – just like playdoh. It can then be made into something new, or used to repair something broken. If you don’t like what you’ve made, remelt and remould!!

At hotter temperatures, the plastic becomes sticky and this is what you need if you want your creation to adhere to other plastics (like the broken throttle lever on our mower). When the plastic sets, it becomes hard and durable so it’s strong enough to make basic tools, hooks, handles, bespoke mobile phone holders….You are only limited by your imagination!!

We love the idea that there is now a tool we can use to repair things that would otherwise need a costly replacement or worse, have to be thrown away!! And there is more good news….the bio-plastic is made from plant based materials and is completely biodegradable. So when you have finished with it, you can chuck your FORMcard on the compost. To find out more about this little miracle worker, read my other post titled FORMcard – the repair tool every home should have.

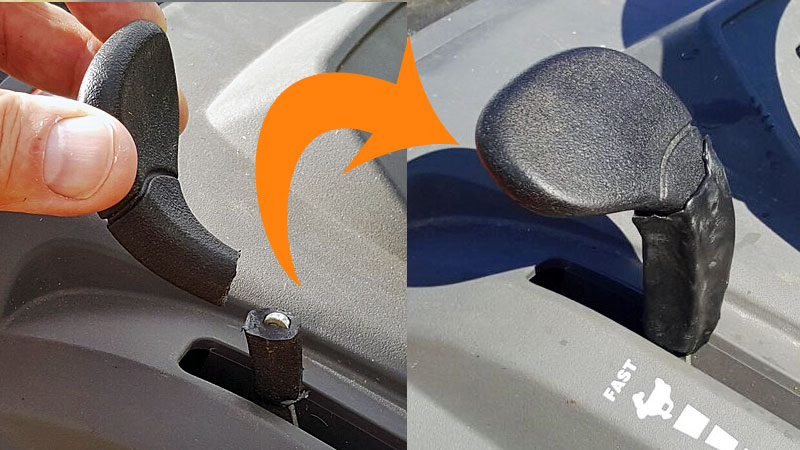

So, let’s take a look at our poor mower…. The throttle lever snapped off and even a good dose of superglue wouldn’t have stood a chance with this plastic repair. So we gave the FORMcard a test run, and this is how it went.

1. The Problem

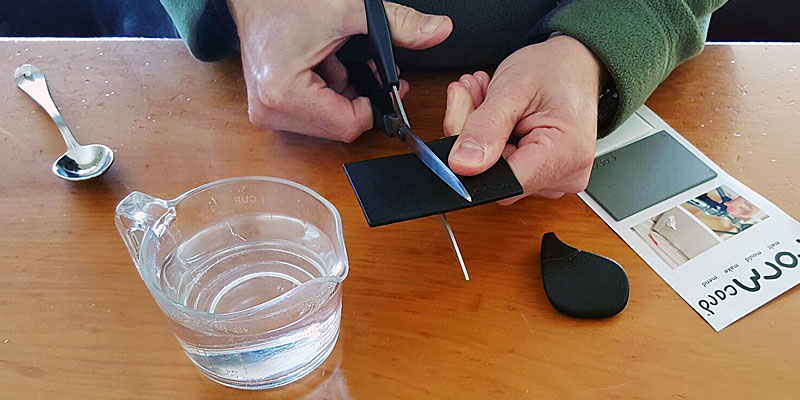

2. Assemble the Toolkit for Your Plastic Repair

This is all the kit you need to get mending with your FORMcard. The jug/mug will need to be full of hot water though….!!

3. Cut your FORMcard to Size

Each plastic repair will be different and you might not need a whole card, so cut the cards to size before you soften them. The cards are easy to cut with normal stationery scissors.

4. Drop the Bioplastic Card into Hot Water

5. Wait for the FORMcard to Soften in the Hot Water

It doesn’t take long – a couple of minutes is all that’s needed for the plastic to become pliable.

6. Remove the Melted Card from the Water

Use a spoon or tool for this to avoid burning your fingers. The plastic itself might be too hot to touch as you take it out of the water, but it cools down very quickly (in a few seconds).

7. Quickly Mould to the Required Shape

Work quickly while your card is still soft. You’ll see our handle is plastic and for the FORMcard to adhere to other plastics it needs to be tacky. The first time we tried our repair, the card wasn’t hot enough so didn’t stick to the handle. So we simply peeled it off and put it back in the hot water for a bit longer until it became sticky.

8. Finish Moulding FORMcard Around the Handle

9. Broken Plastic Handle “As Good As New”!

And…Yay, it worked!!

The FORMcard has set to become solid and strong, reforming the shape and function of the handle. I can’t think of any other ways we could have done this repair that would have any chance of lasting!!

The idea behind FORMcard came from Peter Marigold; a specialist in plastics who wished to give us a tool to repair and create in the hope that less everyday items end up in landfill. He sees FORMcards sitting alongside blu-tack and sellotape in the kitchen drawer, or as part of a toolkit kept in your car or in the fishing box.

Having tried it, we can see it’s effective and really…the options are endless. So next time you need to perform an impossible repair, these little cards might be just what you need.

Please Note: Unfortunately FORMcards are no longer available on Green Elephant or in New Zealand but they can be purchased from FORMcard in the UK and shipped internationally.